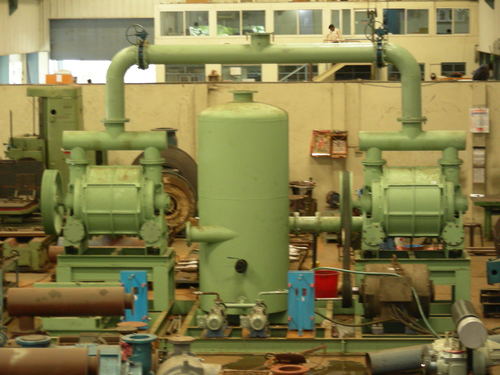

Double Stage Water Ring Vacuum Pump

Price 100000 INR/ Piece

MOQ : 1 Piece

Double Stage Water Ring Vacuum Pump Specification

- Theory

- Vacuum Pump

- Material

- Stainless steel, Mild Steel

- Structure

- Other

- Power

- Electric Volt (v)

- Color

- Sky Blue

- Usage

- Water

Double Stage Water Ring Vacuum Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 3-4 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- Main Domestic Market

- All India

About Double Stage Water Ring Vacuum Pump

Double Stage Water Ring Vacuum Pump is basically the multistage pump which is driven by hydraulic power. It is utilized for drawing insoluble gases and air free from solid particles. It is mainly used for vacuum concentration, vacuum vaporization and vacuum drying procedures. This high pressure pump is reckoned for its high operating speed, low maintenance design, space saving look and low energy usage rate. Its stainless steel or cast iron structure is corrosion proof. Utilization of latest accessories and precise diameter are its main factors. We are an eminent manufacturer and exporter of best grade Double Stage Water Ring Vacuum Pump.

Features of Double Stage Water Ring Vacuum Pump:

- Multistage operation

- High efficiency level

- Cast iron or stainless steel body

- Low noise level

Warning:

- Do not carry out any maintenance while the pump is connnected to the motor.

- Never start or stop the pump without water

- Never increase height of water outlet from pump silencer. It will absorb more power and tripping of electric motor.

- It is advisable to check the water hardness and incase of this exceed and tolerance limits (50 to 150 PPM) a proper purification system should be provided.

- Do not loose or tighten bearing cover bolts without any instruction.

Proper Foundation:

- Correct foundations and installations are essential to assure a safe operation. A non compliance with the norms of correct foundation and installation could cause pump failures.

- The pump must be installed on flat surface, rigid enough to withstand its weight and suitable to withstand the loads cause by the motor mechanism and by the pump operation.

- In order to avoid vibration or wear of the coupling, it is necessary to keep a correct alignment during continuos operation conditions.

Maintenance:

The pump requires only little maintenance. However, the following points must be observed.

- The bearings shall be lubricated after approximately 10,000 service hours.

- The mechanical seals do not require any maintenance. With normal operation, leakage's occur only after several 1000 service hours if parts subject to wear are used up.

- In case of risk of freezing, the pump, the liquid separator and the pipelines are to be drained if necessary, the pump is to be preserved.

- If the pump is required to be storage for long time, drain water completely by opening two plugs at the bottom of casing cover. Fill the lubrication oil from

- suction flange.

- In case strongly calcareous water is used as service liquid, the pump has to be opened at least in a period of six months in order to remove the calcareous(scale) deposits.

- The calcareous deposits can be avoided if the service liquid is prepared with a suitable agent. The measures to be taken depend on operation time and water quality.

- In case the pump has not been in operation for a longer period of time, it must be drained.

Connections Of Vacuum Pump

Pipelines:

- Pay attention to the arrows at the pump pipe line indicating the flow direction.

- The nominal widths of the pipelines must not be smaller than the nominal widths of the corresponding pump branches.

- All pipelines must be cleaned prior to installation of the pump.

- The pipelines must be supported in order to avoid distortions of the pump components (danger of breaking of the pump components).

- The suction, discharge and service liquid lines must be as short as possible and their cross-section must be as least as the corresponding pump connections. For long pipelines larger cross sections are required.

- Identify first locations and dimensions of all connections required to interconnected the pump with the installation, then proceed with the actual piping.

Suction Line

A non-return valve should be installed in the suction line. It prevents back flow of gas and liquid in the suction piping when the pump stopped.

If the pump shall be started-up or stopped with closed shutoff element, e.g. Valve in the suction line, cavitation occurs, too.

Discharge Line

The discharge line must not be led more than 1m vertically or diagonally upwards. If a shutoff element is installed in the discharge line behind the liquid separator, it must be ensured that the pump cannot be put into operation while this shutoff element is closed.

Seal Water Line

For a good operation the watering vacuum pumps must be supplied with a seal water which is clean, non abrasive and of any solids. The service seal water should not exceed 30.31 degree centigrade and the gas handled should be maximum 90 degree centigrade.

Specification

|

Brand |

PPI |

|

Voltage |

415 |

|

Product Weight |

100 kg |

|

Country of Origin |

Made in India |

|

Material |

CI/SS |

FAQs of Double Stage Water Ring Vacuum Pump:

Q: What is the power source for Double Stage Water Ring Vacuum Pump?

A: The power source for Double Stage Water Ring Vacuum Pump is Electric Volt (v).Q: What is the color of Double Stage Water Ring Vacuum Pump?

A: The color of Double Stage Water Ring Vacuum Pump is Sky Blue.Q: What is the usage of Double Stage Water Ring Vacuum Pump?

A: Double Stage Water Ring Vacuum Pump is used in Chemicals, Pharmaceuticals & Process Industries, and Water.Q: What is the material used to manufacture Double Stage Water Ring Vacuum Pump?

A: The material used to manufacture Double Stage Water Ring Vacuum Pump is Stainless steel and Mild Steel.Q: What is the theory behind Double Stage Water Ring Vacuum Pump?

A: The theory behind Double Stage Water Ring Vacuum Pump is Vacuum Pump.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Water Ring Vacuum Pump Category

Single Stage Water Ring Vacuum Pump

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Sky Blue

Theory : Vacuum Pump

Material : Stainless steel, Mild Steel

Power : Electric Volt (v)

Cone Type Water Ring Vacuum Pump

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Sky Blue

Theory : Vacuum Pump

Material : Stainless steel, Mild Steel

Power : Electric Watt (w)

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese